Thanks to the expertise and experience acquired from over 30 years in the sector, we have developed a set of comprehensive services in order to satisfy our customers’ every need.

- Custom: an entire department dedicated to creating projects for every need. From the development of large-scale work orders, such as offshore projects, airports, etc., to customising every single piece.

- Dynamic and flexible metalworking to create any type of structure, with many customisation options.

- In-house design with a qualified technical department that uses the latest technologies.

- Electro-welded grating: one of the widest and most varied ranges on the European market.

- Fences: More than 20 different types, including residential, industrial, sports, street furniture and construction site models.

- Building material accessories: the range includes block pavior manhole covers, grates with a frame, steel cover plates, tank lids, hardware, various stainless steel accessories and more.

- Large production department: over 10,000 square metres of cutting-edge machinery for industrial-scale production and to customise each of our products.

- Versatile production: to satisfy any stylistic and structural need.

- Automated warehouse to manage and execute every order optimally and efficiently.

- Our own means of transport to guarantee a fast and timely delivery.

- Affiliated carriers so we can reach everywhere, including the most remote places.

- A wide choice of products are always held in stock for immediate dispatch.

- Technical advice during the pre-sales phase.

- Decades of experience solving technical and aesthetic problems.

- Support managing any post-purchase issues.

- Feedback collected from our customers in order to help us improve the quality of our products and services, in addition to providing new solutions in line with market needs.

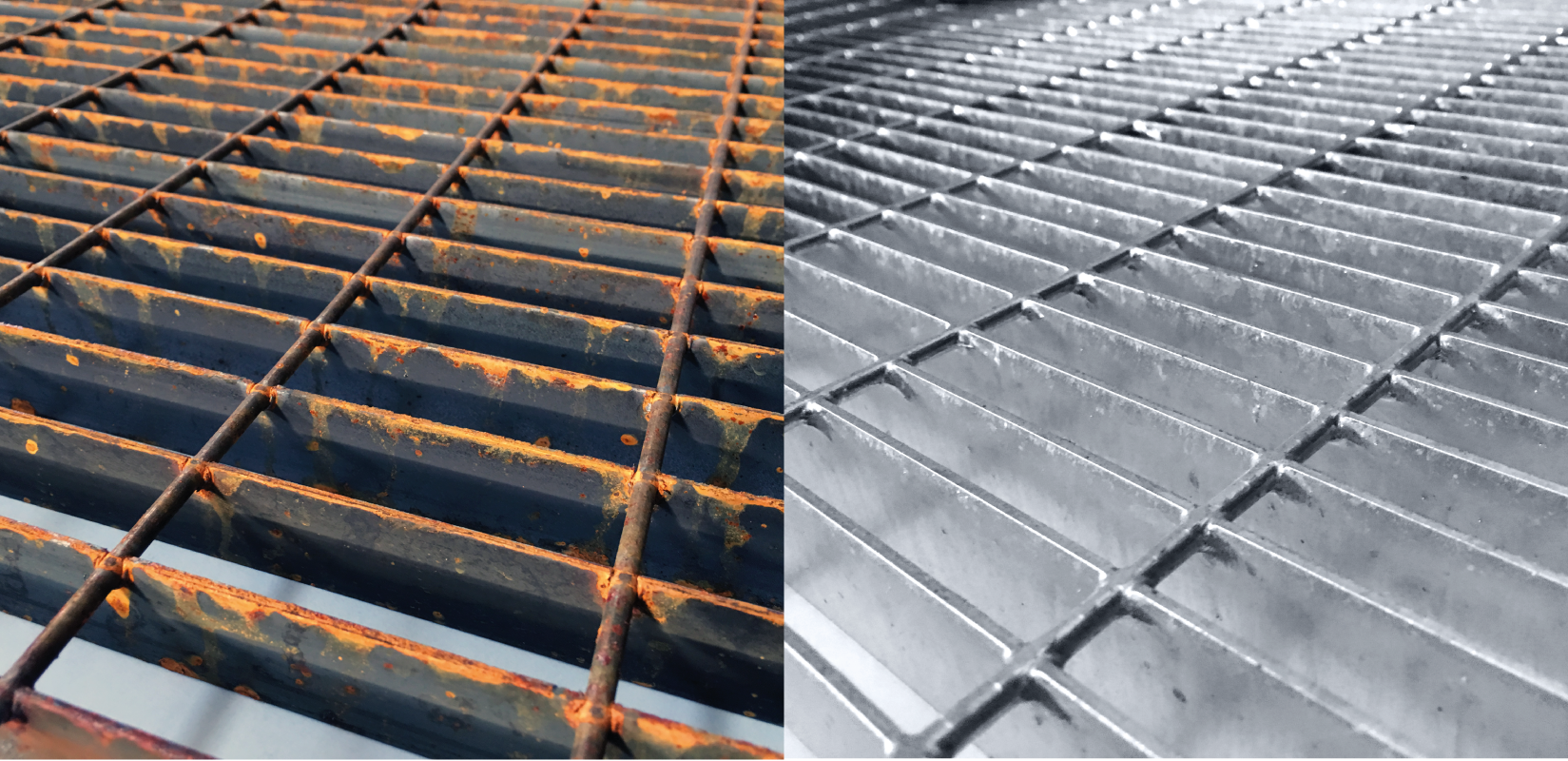

Galvanising and Colour-Coating

Galvanising

Hot-dip galvanising is one of the most popular methods for protecting steel products from rust. This process is carried out by applying a layer of zinc on the product; it protects the underlying steel and protects it from oxidation, thus preserving all the material’s characteristics. The galvanising process is performed by immersing the workpieces in a tank of molten zinc at about 450°C for a time proportional to the desired coating thickness: the longer the immersion, the thicker the galvanising layer, and therefore, the greater the protection against rust and scratches. Rust is a very common problem for any ferrous product and the risk of compromising the product’s mechanical-structural resistance is very high: the pieces treated with our galvanising process last 10 times longer than untreated products (source: BS 5493/1977). In accordance with the Common Rules of the CEN/CENELEC, the member countries of the European Committee for Standardization (CEN), including Italy, are required to adopt and indicate the UNI EN ISO 1461:2009 standard for galvanising.

Design and colour

The processing technologies and possible design combinations are elements that make the grating a product that is increasingly being chosen to respond to various, diverse solutions. Baldassar is able to custom-design the most varied shapes, by drawing upon its own experience to find solutions for the various technical problems that could occur during the projects. A wide range of colours is available.