Electro-Welded

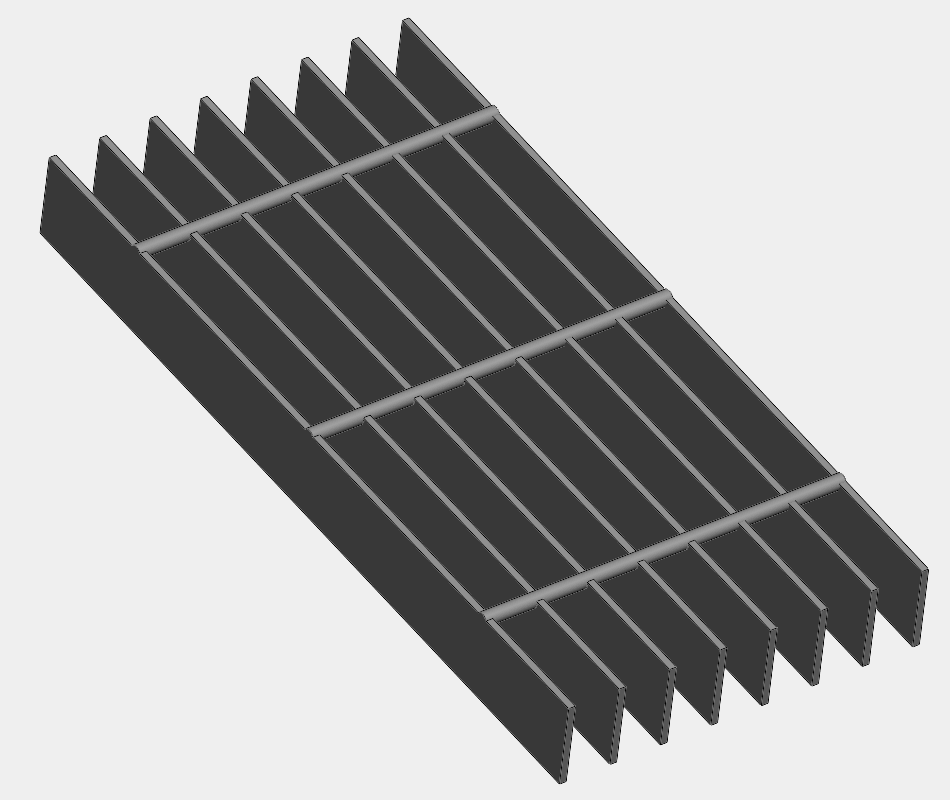

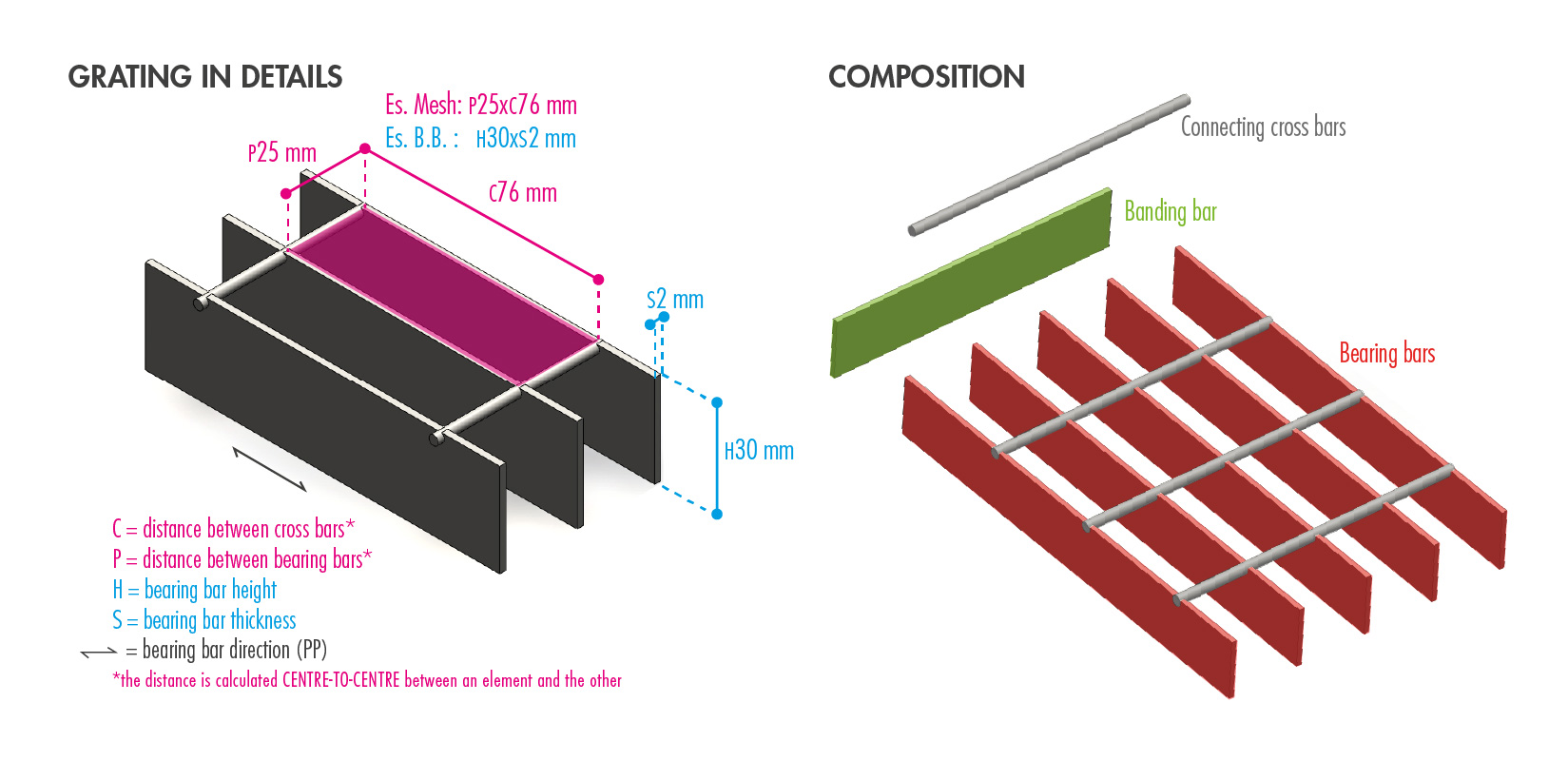

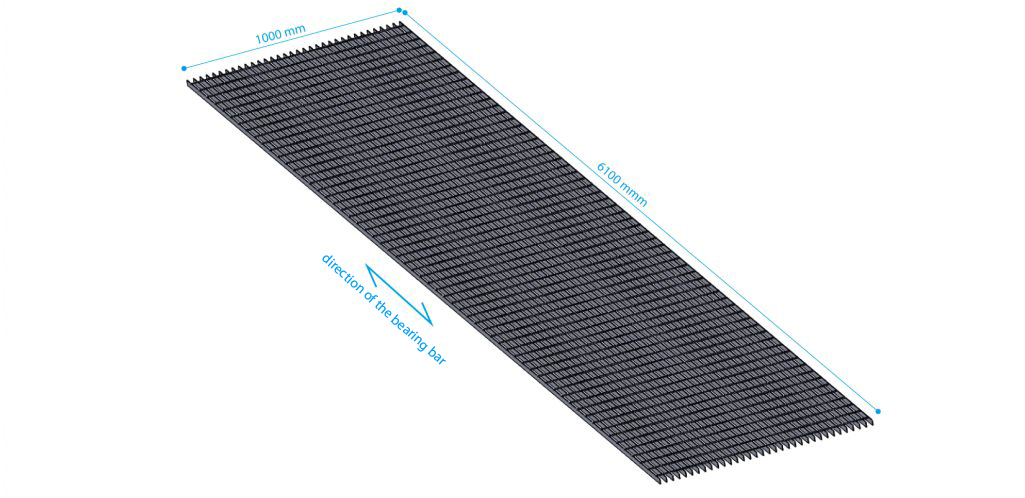

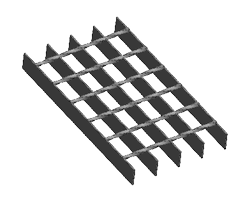

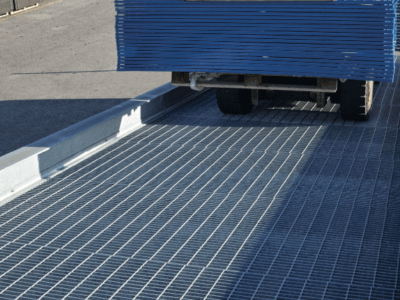

Due to the electro-welded grating’s high twist resistance and balanced load distribution, these products boast an unlimited service life. It consists of bearing bars intersected with smooth round or square twisted cross bars, electro-welded together via a single pressing phase. The bearing bars have variable cross-sections, ranging from a minimum of 20 x 2 mm to a maximum of 100 x 5 mm. The bearing bars, in combination with the type of mesh used, determine the load-bearing capacity of the panels. The cross bars have the function of connecting the bars, ensuring grating stability and increasing the load capacity.

Types of standard electro-welded grating

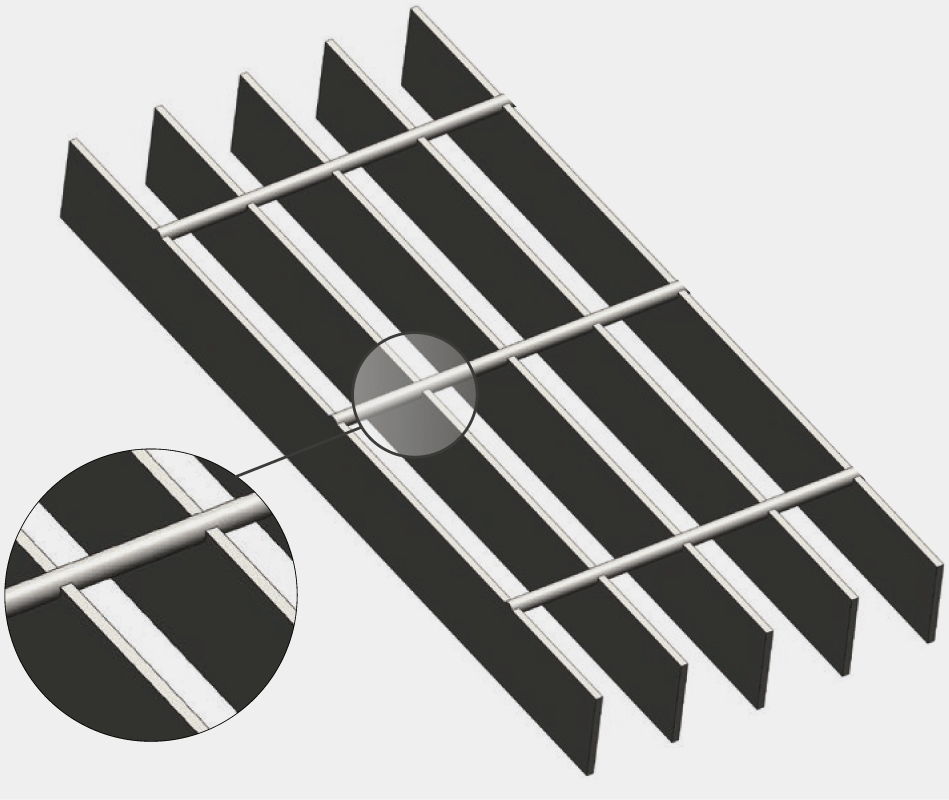

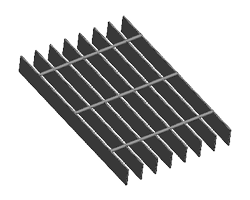

The electro-welded grating with smooth round cross bars ensures a stable grating, whilst also increasing the load capacity and ensuring high operating performance, in addition to providing a high aesthetic value.

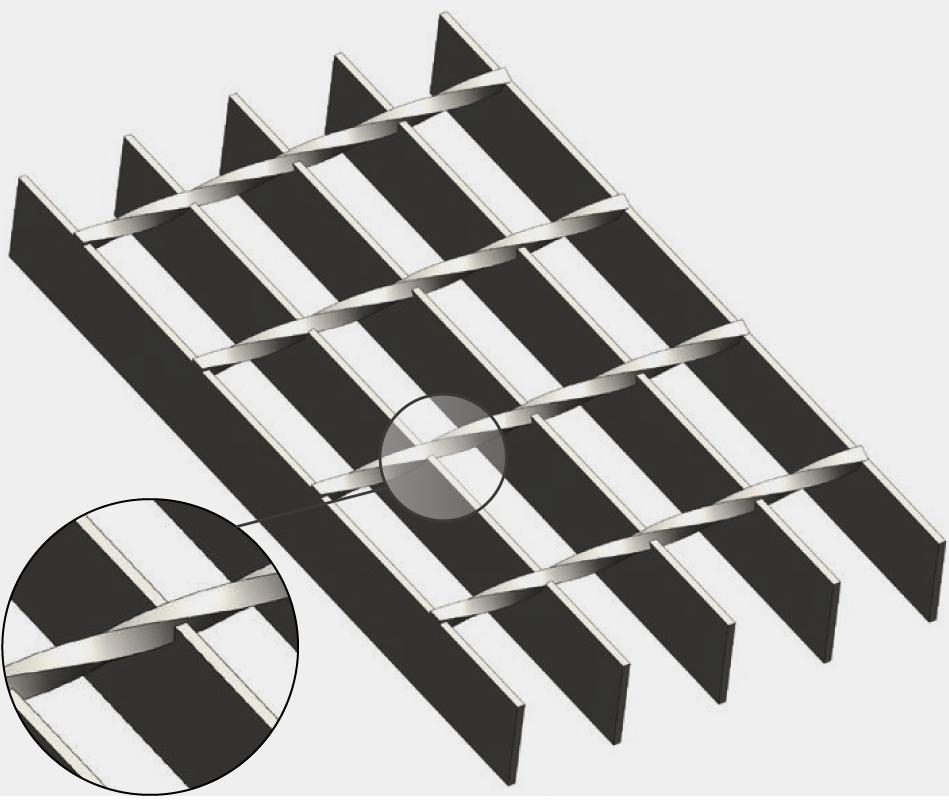

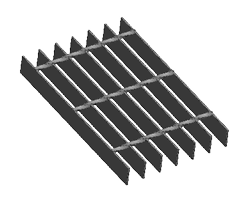

The electro-welded grating with twisted square cross bars is mainly used in slippery areas and ensures a stable grating, whilst also increasing the load capacity and ensuring high operating performance. They are recommended for industrial areas where there is a risk of slipping.

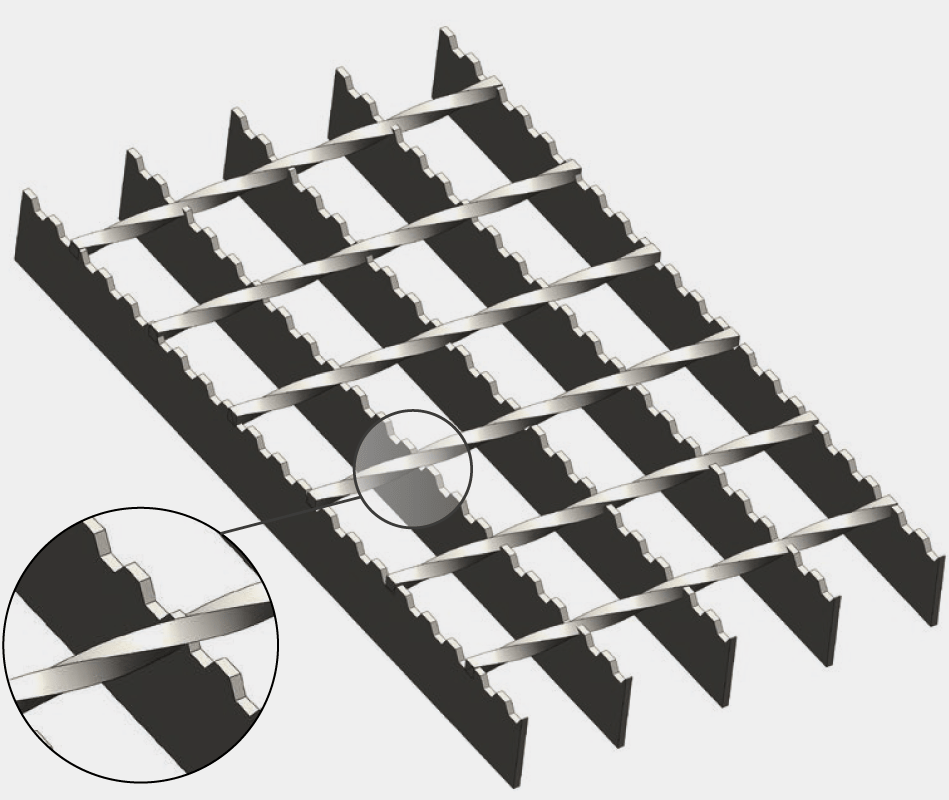

The serrated grating is created by using laminate or sheared bearing bars with a surface consisting of suitably-shaped teeth which are usually connected by twisted square cross bars. This particular combination has been designed to meet the accident prevention regulations, where a particular non-slip function is required. It is widely recommended for any environments that work with liquids or oily substances.

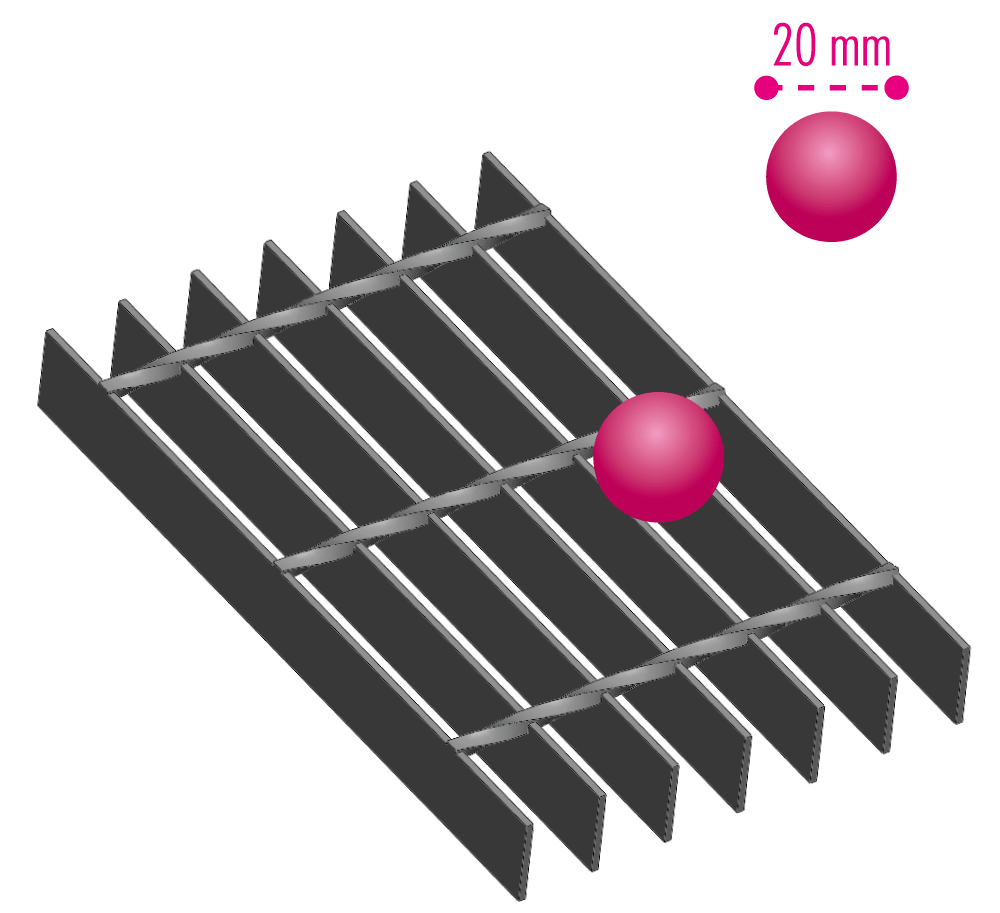

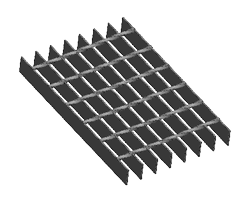

This grating for industrial flooring consists of meshes that prevent a 20 mm-diameter ball from passing through. Recommended for environments where fall protection is needed.

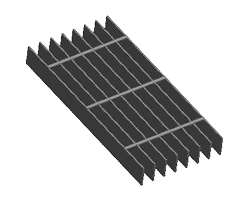

The term “heel-proof” has no regulatory reference but is commonly used to define a grating that has bearing bars with a centre-to-centre distance of 15 mm or less. It is usually used in the civil sector, wherever there is a high pedestrian footfall.

Advantages

- Endless possible applications: from the civil construction section to offshore projects.

- Extremely resistant and inexpensive: it supports heavy loads in all installation conditions.

- Ultra-versatile in terms of shape and product: allows various and special shapes to be produced.

Single panel

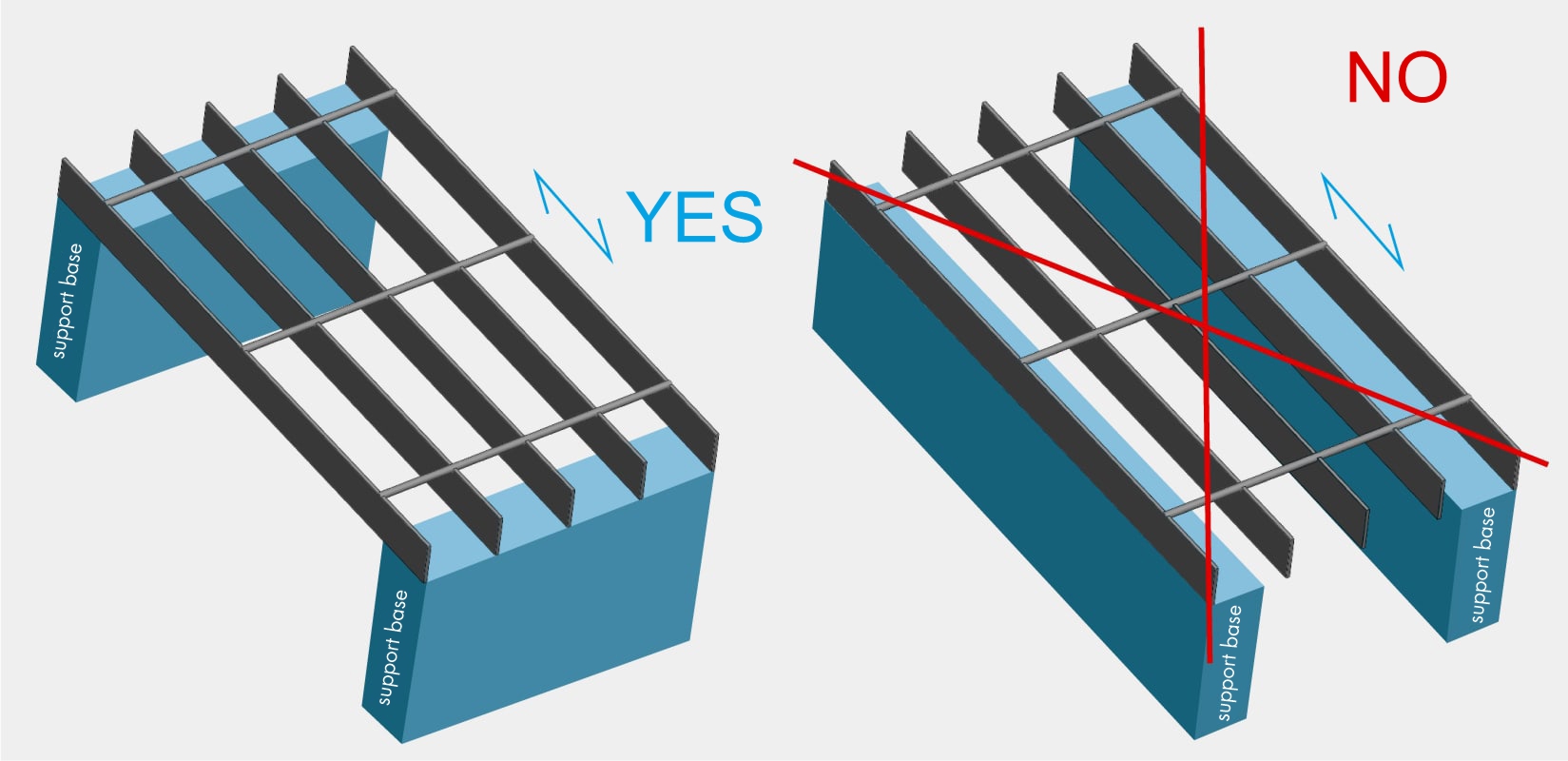

The values shown in the load classes are only and exclusively guaranteed if the direction of the planes on which the Baldassar Electro-Welded Grating panel rests is perpendicular to the direction of the load-bearing bars; if it is parallel to the direction of the load-bearing bars, the panel’s load-bearing capacity would be severely compromised.

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**) | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 20x2 | ○ 4mm | 6100x1000 | 21,0 | 22,4 | 1045 | 231 | 176 | 138 |

| 25x2 | ○ 4mm | 6100x1000 | 25,2 | 27,0 | 1235 | 305 | 222 | 173 |

| 25x2 | ○ 4mm | 6100x1200 | 25,2 | 27,0 | 1235 | 305 | 222 | 173 |

| 30x2 | ○ 4mm | 6100x1000 | 30,8 | 33,0 | 1417 | 395 | 276 | 208 |

| 30x2 | ○ 4mm | 6100x1200 | 30,7 | 33,0 | 1417 | 395 | 276 | 208 |

| 30x2D* | ◻︎ 5 mm | 6100x1000 | 30,6 | 32,8 | 1417 | 395 | 276 | 208 |

| 40x2 | ○ 4mm | 6100x1000 | 40,7 | 43,5 | 1758 | 625 | 374 | 278 |

| 25x3 | ○ 5mm | 6100x1000 | 39,6 | 42,3 | 1367 | 407 | 283 | 212 |

| 30x3 | ○ 5mm | 6100x1000 | 46,3 | 49,6 | 1568 | 543 | 343 | 254 |

| 40x3 | ○ 5mm | 6100x1000 | 62,1 | 66,4 | 1945 | 887 | 462 | 352 |

| 50x3 | ○ 5mm | 6100x1000 | 77,1 | 82,5 | 2300 | 1330 | 610 | 440 |

| 60x3 | ○ 5mm | 6100x1000 | 92,2 | 98,6 | 2637 | 1653 | 790 | 528 |

| 70x3* | ○ 5mm | 6100x1000 | 107,2 | 114,7 | 2960 | 1928 | 1004 | 616 |

| 80x3* | ○ 5mm | 6100x1000 | 122,2 | 130,8 | 3272 | 2202 | 1250 | 713 |

| 90x3* | ○ 5mm | 6100x1000 | 137,2 | 146,8 | 3574 | 2477 | 1529 | 823 |

| 100x3* | ○ 5mm | 6100x1000 | 152,3 | 162,9 | 3868 | 2752 | 1841 | 946 |

| 50x4* | ○ 5mm | 6100x1000 | 103,0 | 110,2 | 2471 | 1517 | 747 | 508 |

| 60x4* | ○ 5mm | 6100x1000 | 123,2 | 131,9 | 2834 | 1819 | 987 | 610 |

| 70x4* | ○ 5mm | 6100x1000 | 143,4 | 153,5 | 3181 | 2121 | 1272 | 722 |

| 80x4* | ○ 5mm | 6100x1000 | 163,6 | 175,1 | 3516 | 2423 | 1600 | 851 |

| 90x4* | ○ 5mm | 6100x1000 | 183,9 | 196,7 | 3841 | 2726 | 1901 | 998 |

| 100x4* | ○ 5mm | 6100x1000 | 204,1 | 218,3 | 4157 | 3028 | 2110 | 1162 |

| Not always available on stock | ||||||||

| **Load Bearing classes refers to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**) | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 25x2 | ○ 4mm | 6100x1000 | 16,6 | 17,7 | 1087 | 238 | 177 | 136 |

| 25x2 | ○ 4mm | 6100x1200 | 16,6 | 17,7 | 1087 | 238 | 177 | 136 |

| 30x2 | ○ 4mm | 6100x1000 | 19,6 | 21,0 | 1247 | 298 | 213 | 164 |

| 30x2 | ○ 4mm | 6100x1200 | 19,6 | 21,0 | 1247 | 298 | 213 | 164 |

| 40x2 | ○ 4mm | 6100x1000 | 25,7 | 27,5 | 1547 | 453 | 302 | 218 |

| 25x3 | ○ 5mm | 6100x1000 | 25,3 | 27,1 | 1203 | 307 | 218 | 167 |

| 30x3 | ○ 5mm | 6100x1000 | 29,8 | 31,9 | 1380 | 398 | 270 | 201 |

| 40x3 | ○ 5mm | 6100x1000 | 39,3 | 42,1 | 1712 | 629 | 375 | 268 |

| 50x3 | ○ 5mm | 6100x1000 | 48,7 | 52,1 | 2024 | 928 | 476 | 349 |

| 60x3 | ○ 5mm | 6100x1000 | 58,0 | 62,1 | 2321 | 1292 | 597 | 433 |

| 70x3* | ○ 5mm | 6100x1000 | 67,3 | 72,1 | 2605 | 1690 | 741 | 505 |

| 80x3* | ○ 5mm | 6100x1000 | 76,7 | 82,0 | 2880 | 1930 | 906 | 577 |

| 40x4 | ○ 6mm | 6100x1000 | 53,1 | 56,8 | 1840 | 806 | 435 | 316 |

| 50x4 | ○ 6mm | 6100x1000 | 65,6 | 70,2 | 2175 | 1204 | 568 | 416 |

| 60x4 | ○ 6mm | 6100x1000 | 78,2 | 83,7 | 2494 | 1595 | 729 | 500 |

| 70x4 | ○ 6mm | 6100x1000 | 90,8 | 97,1 | 2800 | 1859 | 921 | 583 |

| 80x4* | ○ 6mm | 6100x1000 | 103,3 | 110,5 | 3094 | 2124 | 1142 | 670 |

| 90x4* | ○ 6mm | 6100x1000 | 115,9 | 124,0 | 3380 | 2389 | 1392 | 769 |

| 100x4* | ○ 6mm | 6100x1000 | 128,4 | 137,4 | 3658 | 2654 | 1672 | 879 |

| 70x5* | ○ 6mm | 6100x1000 | 113,3 | 121,2 | 2960 | 2002 | 1101 | 654 |

| 80x5* | ○ 6mm | 6100x1000 | 124,7 | 138,1 | 3272 | 2288 | 1377 | 763 |

| 100x5* | ○ 6mm | 6100x1000 | 160,6 | 171,8 | 3868 | 2858 | 1993 | 1023 |

| *Not always available on stock | ||||||||

| **Load Bearing classes refers to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**) | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 25x2 | ○ 4mm | 6100x1000 | 19,2 | 20,6 | 1087 | 238 | 177 | 136 |

| **Load Bearing classes refers to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm** | CL3 clean light (mm**) | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 25x2 | ◻︎ 4mm | 6100x1000 | 19,2 | 20,6 | 1123 | 252 | 187 | 144 |

| 30x2 | ◻︎ 4mm | 6100x1000 | 22,6 | 24,2 | 1287 | 320 | 227 | 173 |

| 25x3 | ◻︎ 5mm | 6100x1000 | 28,2 | 30,2 | 1242 | 329 | 232 | 177 |

| 30x3 | ◻︎ 5mm | 6100x1000 | 33,5 | 35,8 | 1425 | 430 | 290 | 212 |

| 30x3D | ◻︎ 5mm | 6100x1000 | 33,3 | 35,6 | 1425 | 430 | 290 | 212 |

| 40x3 | ◻︎ 5mm | 6100x1000 | 44,0 | 47,0 | 1768 | 687 | 395 | 285 |

| 50x3* | ◻︎ 5mm | 6100x1000 | 54,4 | 58,2 | 2090 | 1017 | 505 | 376 |

| 60x3* | ◻︎ 5mm | 6100x1000 | 64,9 | 69,4 | 2396 | 1421 | 640 | 452 |

| 70x3* | ◻︎ 5mm | 6100x1000 | 75,4 | 80,6 | 2690 | 1748 | 799 | 528 |

| 30x4* | ◻︎ 5,5mm | 6100x1000 | 44,3 | 47,4 | 1531 | 540 | 342 | 245 |

| 40x4* | ◻︎ 5,5mm | 6100x1000 | 57,0 | 60,9 | 1900 | 883 | 461 | 339 |

| 50x4* | ◻︎ 5,5mm | 6100x1000 | 70,7 | 75,6 | 2246 | 1323 | 607 | 435 |

| 60x4* | ◻︎ 5,5mm | 6100x1000 | 84,4 | 90,3 | 2575 | 1650 | 787 | 522 |

| 70x4* | ◻︎ 5,5mm | 6100x1000 | 98,1 | 105,0 | 2890 | 1924 | 999 | 609 |

| 80x4* | ◻︎ 5,5mm | 6100x1000 | 111,8 | 119,7 | 3195 | 2198 | 1244 | 704 |

| 70x5* | ◻︎ 5,5mm | 6100x1000 | 127,3 | 136,2 | 3056 | 2072 | 1199 | 687 |

| 80x5* | ◻︎ 5,5mm | 6100x1000 | 145,0 | 155,1 | 3378 | 2367 | 1505 | 805 |

| 100x5* | ◻︎ 5,5mm | 6100x1000 | 180,4 | 193,0 | 3994 | 2958 | 2061 | 1090 |

| *Not always available on stock | ||||||||

| **Load Bearing classes refers to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**) | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 25x2* | ◻︎ 4 mm | 6100x1000 | 20,0 | 21,4 | 1123 | 252 | 187 | 144 |

| 30X2* | ◻︎ 4 mm | 6100x1000 | 23,5 | 25,2 | 1287 | 320 | 227 | 173 |

| *Not always available on stock | ||||||||

| **Load Bearing classes refers to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**) | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 25x2 | ◻︎ 4 mm | 6100x1000 | 21,3 | 22,8 | 1123 | 252 | 187 | 144 |

| **Load Bearing classes refers to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**)[ | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 25x3 | ◻︎ 5 mm | 6100x1000 | 22,5 | 24,1 | 1150 | 265 | 198 | 154 |

| 30x3 | ◻︎ 5 mm | 6100x1000 | 26,4 | 28,2 | 1318 | 339 | 242 | 184 |

| 30x3D | ◻︎ 5 mm | 6100x1000 | 26,2 | 28,0 | 1318 | 339 | 242 | 184 |

| 40x3 | ◻︎ 5 mm | 6100x1000 | 34,1 | 36,5 | 1636 | 524 | 336 | 246 |

| 40x4 | ◻︎ 5,5 mm | 6100x1000 | 46,9 | 50,2 | 1758 | 666 | 388 | 286 |

| 30x5 | ◻︎ 5,5 mm | 6100x1000 | 44,5 | 47,6 | 1449 | 457 | 312 | 227 |

| 30x5D | ◻︎ 5,5 mm | 6100x1000 | 42,2 | 45,2 | 1449 | 457 | 312 | 227 |

| **Load Bearing classes refer to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**)[ | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 25x3 | ◻︎ 5 mm | 6100x1000 | 20,9 | 22,4 | 1150 | 265 | 198 | 154 |

| 30x3 | ◻︎ 5 mm | 6100x1000 | 24,8 | 26,5 | 1318 | 339 | 242 | 184 |

| 30x3D | ◻︎ 5 mm | 6100x1000 | 24,6 | 26,3 | 1318 | 339 | 242 | 184 |

| 40x3 | ◻︎ 5 mm | 6100x1000 | 32,6 | 34,8 | 1636 | 524 | 336 | 246 |

| 40x4 | ◻︎ 5,5 mm | 6100x1000 | 44,3 | 47,4 | 1758 | 666 | 388 | 286 |

| 30x5 | ◻︎ 5,5 mm | 6100x1000 | 41,9 | 44,8 | 1449 | 457 | 312 | 227 |

| 30x5D | ◻︎ 5,5 mm | 6100x1000 | 41,7 | 44,6 | 1449 | 457 | 312 | 227 |

| 40x5 | ◻︎ 5,5 mm | 6100x1000 | 55,0 | 58,8 | 1859 | 808 | 436 | 327 |

| **Load Bearing classes refer to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**)[ | CL4 clean light (mm**) |

|---|---|---|---|---|---|---|---|---|

| 25x2 | ◻︎ 4 mm | 6100x1000 | 15,0 | 16,1 | 1007 | 195 | 150 | 116 |

| 30x2 | ◻︎ 4 mm | 6100x1000 | 17,6 | 18,8 | 1154 | 237 | 180 | 139 |

| 40x2 | ◻︎ 4 mm | 6100x1000 | 22,0 | 23,6 | 1432 | 345 | 245 | 186 |

| 25x3 | ◻︎ 5 mm | 6100x1000 | 21,2 | 22,7 | 1114 | 243 | 184 | 142 |

| 25x3D* | ◻︎ 5 mm | 6100x1000 | 21,0 | 22,5 | 1114 | 243 | 184 | 142 |

| 30x3 | ◻︎ 5 mm | 6100x1000 | 24,6 | 26,3 | 1278 | 306 | 222 | 171 |

| 30x3D | ◻︎ 5 mm | 6100x1000 | 24,4 | 26,1 | 1278 | 306 | 222 | 171 |

| 40x3* | ◻︎ 5 mm | 6100x1000 | 31,5 | 33,7 | 1585 | 467 | 313 | 228 |

| 50x3* | ◻︎ 5 mm | 6100x1000 | 38,3 | 41,0 | 1874 | 674 | 391 | 288 |

| 30x4* | ◻︎ 5,5 mm | 6100x1000 | 31,7 | 33,9 | 1373 | 375 | 263 | 197 |

| 40x4* | ◻︎ 5,5 mm | 6100x1000 | 40,9 | 43,7 | 1704 | 590 | 361 | 264 |

| 50x4* | ◻︎ 5,5 mm | 6100x1000 | 51,6 | 55,2 | 2014 | 865 | 455 | 342 |

| *Not always available on stock | ||||||||

| **Load Bearing classes refer to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Raw (kg/sqm) | Galvanized (kg/sqm) | CL1 clean light (mm**) | CL2 clean light (mm**) | CL3 clean light (mm**) | CL4 clean light (mm**)[ |

|---|---|---|---|---|---|---|---|---|

| 25x2 | ◻︎ 5 mm | 6100x1000 | 12,8 | 13,7 | 1007 | 195 | 150 | 116 |

| 30x2 | ◻︎ 5 mm | 6100x1000 | 15,5 | 16,6 | 1154 | 237 | 180 | 139 |

| 40x2 | ◻︎ 5 mm | 6100x1000 | 20,0 | 21,4 | 1432 | 345 | 245 | 186 |

| 25x3 | ◻︎ 5 mm | 6100x1000 | 19,1 | 20,5 | 1114 | 243 | 184 | 142 |

| 30x3 | ◻︎ 5 mm | 6100x1000 | 22,6 | 24,1 | 1278 | 306 | 222 | 171 |

| 40x3 | ◻︎ 5 mm | 6100x1000 | 29,4 | 31,4 | 1585 | 467 | 313 | 228 |

| 60x3* | ◻︎ 5 mm | 6100x1000 | 43,0 | 46,1 | 2149 | 927 | 475 | 360 |

| 40x4 | ◻︎ 5,5 mm | 6100x1000 | 38,8 | 41,5 | 1704 | 590 | 361 | 264 |

| 60x4* | ◻︎ 5,5 mm | 6100x1000 | 58,5 | 62,6 | 2309 | 1202 | 567 | 430 |

| *Not always available on stock | ||||||||

| **Load Bearing classes refers to the clean light between placements, i.e. the distance between one support and the other. |

||||||||

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Galvanized (kg/sqm) | Piece No. packaging | Maximum load |

|---|---|---|---|---|---|

| 25x2 | ○ 4mm | 150x1000 | 3,7 | 25 | class 4 |

| 25x2 | ○ 4mm | 200x1000 | 4,6 | 25 | class 3 |

| 25x2 | ○ 4mm | 250x1000 | 5,5 | 25 | class 2 |

| 25x2 | ○ 4mm | 300x1000 | 6,5 | 25 | class 1 |

| 25x2 | ○ 4mm | 400x1000 | 8,3 | 25 | class 1 |

| 25x2 | ○ 4mm | 500x1000 | 10,2 | 25 | class 1 |

| 25x2 | ○ 4mm | 600x1000 | 12,1 | 25 | class 1 |

| 25x2 | ○ 4mm | 700x1000 | 13,9 | 25 | class 1 |

| 25x2 | ○ 4mm | 800x1000 | 15,8 | 25 | class 1 |

| 25x2 | ○ 4mm | 900x1000 | 17,6 | 25 | class 1 |

| 25x2 | ○ 4mm | 1000x1000 | 19,5 | 25 | class 1 |

| 30x3 | ○ 5mm | 250x1000 | 9,5 | 25 | class 4 |

| 30x3 | ○ 5mm | 300x1000 | 11,2 | 25 | class 3 |

| 30x3 | ○ 5mm | 400x1000 | 14,5 | 25 | class 2 |

| 40x3 | ○ 5mm | 150x1000 | 8,2 | 25 | class 4 |

| 40x3 | ○ 5mm | 200x1000 | 10,4 | 25 | class 4 |

| 40x3 | ○ 5mm | 250x1000 | 12,5 | 25 | class 4 |

| 40x3 | ○ 5mm | 300x1000 | 14,7 | 25 | class 4 |

| 40x3 | ○ 5mm | 400x1000 | 19,0 | 25 | class 3 |

| 40x3 | ○ 5mm | 500x1000 | 23,3 | 25 | class 2 |

| 40x3 | ○ 5mm | 600x1000 | 27,7 | 25 | class 2 |

| 40x3 | ○ 5mm | 700x1000 | 32,0 | 25 | class 2 |

| 40x3 | ○ 5mm | 800x1000 | 36,3 | 25 | class 1 |

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

| Plate (mm) | Connection | Dimensions (mm) | Galvanized (kg/sqm) | Piece No. packaging | Maximum load |

|---|---|---|---|---|---|

| 25x2 | ○ 4mm | 150x1000 | 5,3 | 25 | class 4 |

| 25x2 | ○ 4mm | 200x1000 | 6,8 | 25 | class 4 |

| 25x2 | ○ 4mm | 250x1000 | 8,2 | 25 | class 3 |

| 25x2 | ○ 4mm | 300x1000 | 9,7 | 25 | class 2 |

| 25x2 | ○ 4mm | 400x1000 | 12,7 | 25 | class 1 |

| 25x2 | ○ 4mm | 500x1000 | 15,6 | 25 | class 1 |

| 25x2 | ○ 4mm | 600x1000 | 18,6 | 25 | class 1 |

| 25x2 | ○ 4mm | 700x1000 | 21,5 | 25 | class 1 |

| 25x2 | ○ 4mm | 800x1000 | 24,5 | 25 | class 1 |

| 25x2 | ○ 4mm | 900x1000 | 27,4 | 25 | class 1 |

| 25x2 | ○ 4mm | 1000x1000 | 30,4 | 25 | class 1 |

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

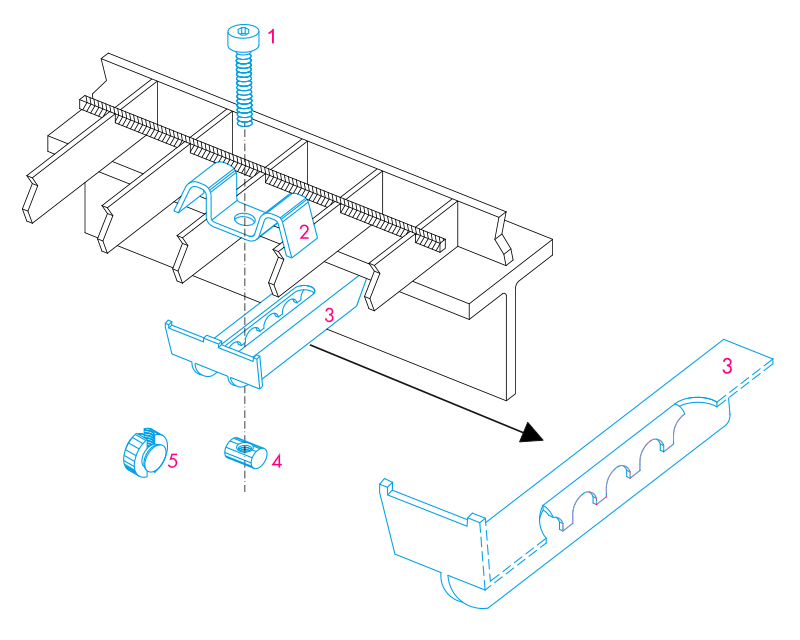

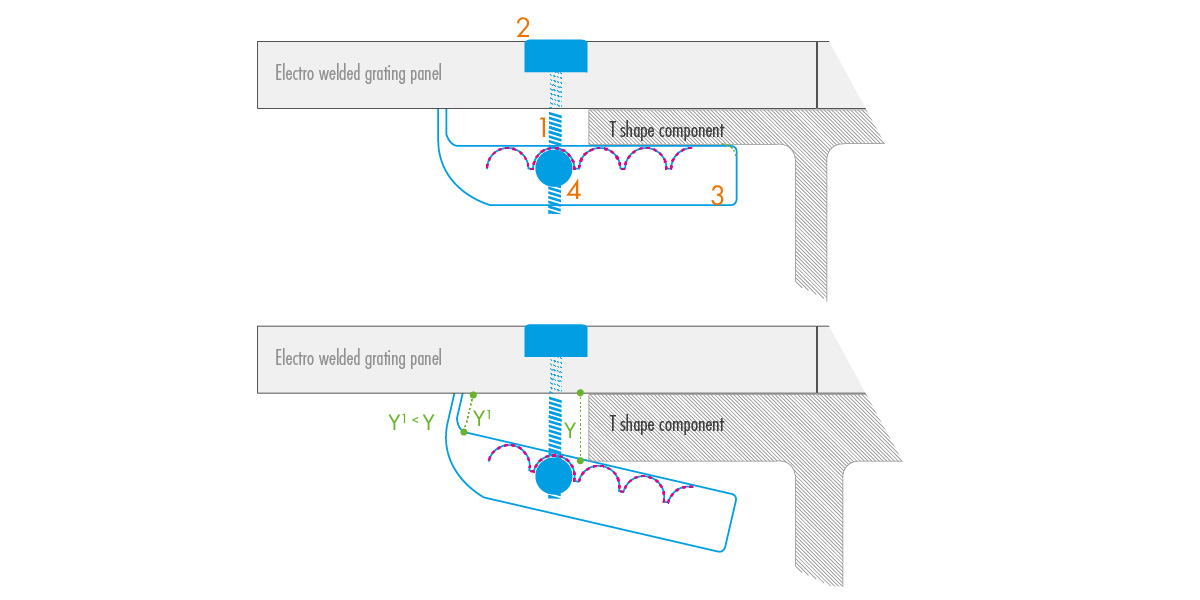

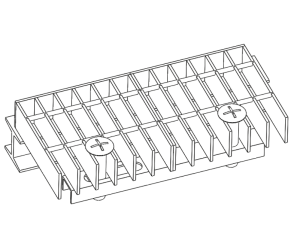

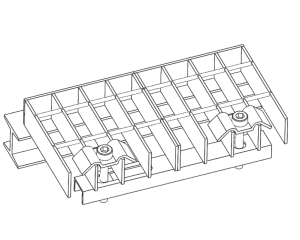

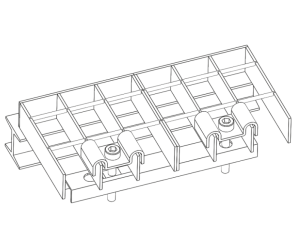

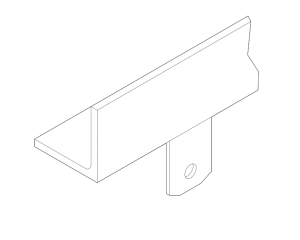

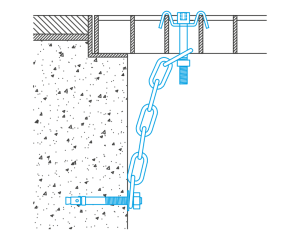

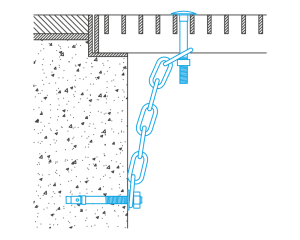

Tank Patented Grating Clamp

1. Traction screw 2. M-shaped clamp 3. Patented grating clamp 4. Standard lock nut 5. Special lock nut

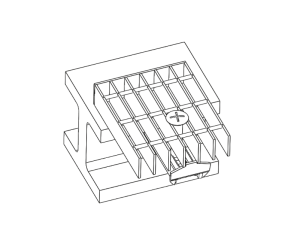

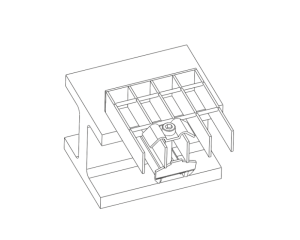

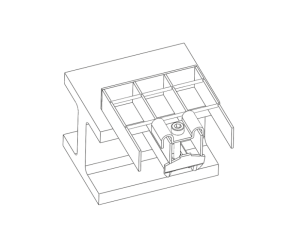

Standard Grating Clamp

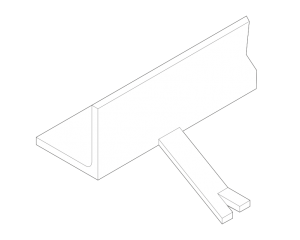

Corner Bars

Anti-Theft Kit

Shaping

Each building and every situation has different shapes and needs. It is for this reason that Baldassar has established a specialised technical department to be able to create products with special shapes and patterns. Thanks to the shaping process, each grating element can have the most suitable contour for an easier insertion and installation, with minimum waste material.

Banding

As a result of the banding process, the grating panel can have various standard finishes or be designed according to the customer’s design, such as with round, bevelled, square or shaped bands. This deformation process is fully designed and performed inside the Baldassar premises.

Calendering

Thanks to the cutting-edge equipment, our technical department is able to deform the metal profiles according to specific designs, by giving it a circular curvature. The process is carried out in-house; therefore, there is no need to wait for third-parties to be carry out this process.

- + Description

-

Electro-Welded

Due to the electro-welded grating’s high twist resistance and balanced load distribution, these products boast an unlimited service life. It consists of bearing bars intersected with smooth round or square twisted cross bars, electro-welded together via a single pressing phase. The bearing bars have variable cross-sections, ranging from a minimum of 20 x 2 mm to a maximum of 100 x 5 mm. The bearing bars, in combination with the type of mesh used, determine the load-bearing capacity of the panels. The cross bars have the function of connecting the bars, ensuring grating stability and increasing the load capacity.

- + Characteristics

-

Types of standard electro-welded grating

The electro-welded grating with smooth round cross bars ensures a stable grating, whilst also increasing the load capacity and ensuring high operating performance, in addition to providing a high aesthetic value.

The electro-welded grating with twisted square cross bars is mainly used in slippery areas and ensures a stable grating, whilst also increasing the load capacity and ensuring high operating performance. They are recommended for industrial areas where there is a risk of slipping.

The serrated grating is created by using laminate or sheared bearing bars with a surface consisting of suitably-shaped teeth which are usually connected by twisted square cross bars. This particular combination has been designed to meet the accident prevention regulations, where a particular non-slip function is required. It is widely recommended for any environments that work with liquids or oily substances.

This grating for industrial flooring consists of meshes that prevent a 20 mm-diameter ball from passing through. Recommended for environments where fall protection is needed.

The term “heel-proof” has no regulatory reference but is commonly used to define a grating that has bearing bars with a centre-to-centre distance of 15 mm or less. It is usually used in the civil sector, wherever there is a high pedestrian footfall.

Advantages

- Endless possible applications: from the civil construction section to offshore projects.

- Extremely resistant and inexpensive: it supports heavy loads in all installation conditions.

- Ultra-versatile in terms of shape and product: allows various and special shapes to be produced.

Single panel

The values shown in the load classes are only and exclusively guaranteed if the direction of the planes on which the Baldassar Electro-Welded Grating panel rests is perpendicular to the direction of the load-bearing bars; if it is parallel to the direction of the load-bearing bars, the panel’s load-bearing capacity would be severely compromised.

- + Meshes and Load Classes

-

15 x 76 mm mesh (heel-proof)

Plate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)CL4

clean light (mm**)20x2 ○ 4mm 6100x1000 21,0 22,4 1045 231 176 138 25x2 ○ 4mm 6100x1000 25,2 27,0 1235 305 222 173 25x2 ○ 4mm 6100x1200 25,2 27,0 1235 305 222 173 30x2 ○ 4mm 6100x1000 30,8 33,0 1417 395 276 208 30x2 ○ 4mm 6100x1200 30,7 33,0 1417 395 276 208 30x2D* ◻︎ 5 mm 6100x1000 30,6 32,8 1417 395 276 208 40x2 ○ 4mm 6100x1000 40,7 43,5 1758 625 374 278 25x3 ○ 5mm 6100x1000 39,6 42,3 1367 407 283 212 30x3 ○ 5mm 6100x1000 46,3 49,6 1568 543 343 254 40x3 ○ 5mm 6100x1000 62,1 66,4 1945 887 462 352 50x3 ○ 5mm 6100x1000 77,1 82,5 2300 1330 610 440 60x3 ○ 5mm 6100x1000 92,2 98,6 2637 1653 790 528 70x3* ○ 5mm 6100x1000 107,2 114,7 2960 1928 1004 616 80x3* ○ 5mm 6100x1000 122,2 130,8 3272 2202 1250 713 90x3* ○ 5mm 6100x1000 137,2 146,8 3574 2477 1529 823 100x3* ○ 5mm 6100x1000 152,3 162,9 3868 2752 1841 946 50x4* ○ 5mm 6100x1000 103,0 110,2 2471 1517 747 508 60x4* ○ 5mm 6100x1000 123,2 131,9 2834 1819 987 610 70x4* ○ 5mm 6100x1000 143,4 153,5 3181 2121 1272 722 80x4* ○ 5mm 6100x1000 163,6 175,1 3516 2423 1600 851 90x4* ○ 5mm 6100x1000 183,9 196,7 3841 2726 1901 998 100x4* ○ 5mm 6100x1000 204,1 218,3 4157 3028 2110 1162 Not always available on stock **Load Bearing classes refers to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

25 x 76 mm meshPlate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)CL4

clean light (mm**)25x2 ○ 4mm 6100x1000 16,6 17,7 1087 238 177 136 25x2 ○ 4mm 6100x1200 16,6 17,7 1087 238 177 136 30x2 ○ 4mm 6100x1000 19,6 21,0 1247 298 213 164 30x2 ○ 4mm 6100x1200 19,6 21,0 1247 298 213 164 40x2 ○ 4mm 6100x1000 25,7 27,5 1547 453 302 218 25x3 ○ 5mm 6100x1000 25,3 27,1 1203 307 218 167 30x3 ○ 5mm 6100x1000 29,8 31,9 1380 398 270 201 40x3 ○ 5mm 6100x1000 39,3 42,1 1712 629 375

268 50x3 ○ 5mm 6100x1000 48,7 52,1 2024 928 476 349 60x3 ○ 5mm 6100x1000 58,0 62,1 2321 1292 597 433 70x3* ○ 5mm 6100x1000 67,3 72,1 2605 1690 741 505 80x3* ○ 5mm 6100x1000 76,7 82,0 2880 1930 906 577 40x4 ○ 6mm 6100x1000 53,1 56,8 1840 806 435 316 50x4 ○ 6mm 6100x1000 65,6 70,2 2175 1204 568 416 60x4 ○ 6mm 6100x1000 78,2 83,7 2494 1595 729 500 70x4 ○ 6mm 6100x1000 90,8 97,1 2800 1859 921 583 80x4* ○ 6mm 6100x1000 103,3 110,5 3094 2124 1142 670 90x4* ○ 6mm 6100x1000 115,9 124,0 3380 2389 1392 769 100x4* ○ 6mm 6100x1000 128,4 137,4 3658 2654 1672 879 70x5* ○ 6mm 6100x1000 113,3 121,2 2960 2002 1101 654 80x5* ○ 6mm 6100x1000 124,7 138,1 3272 2288 1377 763 100x5* ○ 6mm 6100x1000 160,6 171,8 3868 2858 1993 1023 *Not always available on stock **Load Bearing classes refers to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

25 x 25 mm meshPlate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)CL4

clean light (mm**)25x2 ○ 4mm 6100x1000 19,2 20,6 1087 238 177 136 **Load Bearing classes refers to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

22 x 76 mm meshPlate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**CL3

clean light (mm**)CL4

clean light (mm**)25x2 ◻︎ 4mm 6100x1000 19,2 20,6 1123 252 187 144 30x2 ◻︎ 4mm 6100x1000 22,6 24,2 1287 320 227 173 25x3 ◻︎ 5mm 6100x1000 28,2 30,2 1242 329 232 177 30x3 ◻︎ 5mm 6100x1000 33,5 35,8 1425 430 290 212 30x3D ◻︎ 5mm 6100x1000 33,3 35,6 1425 430 290 212 40x3 ◻︎ 5mm 6100x1000 44,0 47,0 1768 687 395 285 50x3* ◻︎ 5mm 6100x1000 54,4 58,2 2090 1017 505 376 60x3* ◻︎ 5mm 6100x1000 64,9 69,4 2396 1421 640 452 70x3* ◻︎ 5mm 6100x1000 75,4 80,6 2690 1748 799 528 30x4* ◻︎ 5,5mm 6100x1000 44,3 47,4 1531 540 342 245 40x4* ◻︎ 5,5mm 6100x1000 57,0 60,9 1900 883 461 339 50x4* ◻︎ 5,5mm 6100x1000 70,7 75,6 2246 1323 607 435 60x4* ◻︎ 5,5mm 6100x1000 84,4 90,3 2575 1650 787 522 70x4* ◻︎ 5,5mm 6100x1000 98,1 105,0 2890 1924 999 609 80x4* ◻︎ 5,5mm 6100x1000 111,8 119,7 3195 2198 1244 704 70x5* ◻︎ 5,5mm 6100x1000 127,3 136,2 3056 2072 1199 687 80x5* ◻︎ 5,5mm 6100x1000 145,0 155,1 3378 2367 1505 805 100x5* ◻︎ 5,5mm 6100x1000 180,4 193,0 3994 2958 2061 1090 *Not always available on stock **Load Bearing classes refers to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

21 x 76 mm mesh (ball-proof)Plate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)CL4

clean light (mm**)25x2* ◻︎ 4 mm 6100x1000 20,0 21,4 1123 252 187 144 30X2* ◻︎ 4 mm 6100x1000 23,5 25,2 1287 320 227 173 *Not always available on stock **Load Bearing classes refers to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

22 x 38 mm meshPlate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)CL4

clean light (mm**)25x2 ◻︎ 4 mm 6100x1000 21,3 22,8 1123 252 187 144 **Load Bearing classes refers to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

30 x 50 mm meshPlate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)[CL4

clean light (mm**)25x3 ◻︎ 5 mm 6100x1000 22,5 24,1 1150 265 198 154 30x3 ◻︎ 5 mm 6100x1000 26,4 28,2 1318 339 242 184 30x3D ◻︎ 5 mm 6100x1000 26,2 28,0 1318 339 242 184 40x3 ◻︎ 5 mm 6100x1000 34,1 36,5 1636 524 336 246 40x4 ◻︎ 5,5 mm 6100x1000 46,9 50,2 1758 666 388 286 30x5 ◻︎ 5,5 mm 6100x1000 44,5 47,6 1449 457 312 227 30x5D ◻︎ 5,5 mm 6100x1000 42,2 45,2 1449 457 312 227 **Load Bearing classes refer to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

30 x 100 mm meshPlate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)[CL4

clean light (mm**)25x3 ◻︎ 5 mm 6100x1000 20,9 22,4 1150 265 198 154 30x3 ◻︎ 5 mm 6100x1000 24,8 26,5 1318 339 242 184 30x3D ◻︎ 5 mm 6100x1000 24,6 26,3 1318 339 242 184 40x3 ◻︎ 5 mm 6100x1000 32,6 34,8 1636 524 336 246 40x4 ◻︎ 5,5 mm 6100x1000 44,3 47,4 1758 666 388 286 30x5 ◻︎ 5,5 mm 6100x1000 41,9 44,8 1449 457 312 227 30x5D ◻︎ 5,5 mm 6100x1000 41,7 44,6 1449 457 312 227 40x5 ◻︎ 5,5 mm 6100x1000 55,0 58,8 1859 808 436 327 **Load Bearing classes refer to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

34 x 38 mm meshPlate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)[CL4

clean light (mm**)25x2 ◻︎ 4 mm 6100x1000 15,0 16,1 1007 195 150 116 30x2 ◻︎ 4 mm 6100x1000 17,6 18,8 1154 237 180 139 40x2 ◻︎ 4 mm 6100x1000 22,0 23,6 1432 345 245 186 25x3 ◻︎ 5 mm 6100x1000 21,2 22,7 1114 243 184 142 25x3D* ◻︎ 5 mm 6100x1000 21,0 22,5 1114 243 184 142 30x3 ◻︎ 5 mm 6100x1000 24,6 26,3 1278 306 222 171 30x3D ◻︎ 5 mm 6100x1000 24,4 26,1 1278 306 222 171 40x3* ◻︎ 5 mm 6100x1000 31,5 33,7 1585 467 313 228 50x3* ◻︎ 5 mm 6100x1000 38,3 41,0 1874 674 391 288 30x4* ◻︎ 5,5 mm 6100x1000 31,7 33,9 1373 375 263 197 40x4* ◻︎ 5,5 mm 6100x1000 40,9 43,7 1704 590 361 264 50x4* ◻︎ 5,5 mm 6100x1000 51,6 55,2 2014 865 455 342 *Not always available on stock **Load Bearing classes refer to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

34 x 76 mm meshPlate (mm) Connection Dimensions (mm) Raw (kg/sqm) Galvanized (kg/sqm) CL1

clean light (mm**)CL2

clean light (mm**)CL3

clean light (mm**)CL4

clean light (mm**)[25x2 ◻︎ 5 mm 6100x1000 12,8 13,7 1007 195 150 116 30x2 ◻︎ 5 mm 6100x1000 15,5 16,6 1154 237 180 139 40x2 ◻︎ 5 mm 6100x1000 20,0 21,4 1432 345 245 186 25x3 ◻︎ 5 mm 6100x1000 19,1 20,5 1114 243 184 142 30x3 ◻︎ 5 mm 6100x1000 22,6 24,1 1278 306 222 171 40x3 ◻︎ 5 mm 6100x1000 29,4 31,4 1585 467 313 228 60x3* ◻︎ 5 mm 6100x1000 43,0 46,1 2149 927 475 360 40x4 ◻︎ 5,5 mm 6100x1000 38,8 41,5 1704 590 361 264 60x4* ◻︎ 5,5 mm 6100x1000 58,5 62,6 2309 1202 567 430 *Not always available on stock **Load Bearing classes refers to the clean light between placements, i.e. the

distance between one support and the other.

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Modular panels with 25 x 76 mm meshPlate (mm) Connection Dimensions (mm) Galvanized (kg/sqm) Piece No. packaging Maximum load 25x2 ○ 4mm 150x1000 3,7 25 class 4 25x2 ○ 4mm 200x1000 4,6 25 class 3 25x2 ○ 4mm 250x1000 5,5 25 class 2 25x2 ○ 4mm 300x1000 6,5 25 class 1 25x2 ○ 4mm 400x1000 8,3 25 class 1 25x2 ○ 4mm 500x1000 10,2 25 class 1 25x2 ○ 4mm 600x1000 12,1 25 class 1 25x2 ○ 4mm 700x1000 13,9 25 class 1 25x2 ○ 4mm 800x1000 15,8 25 class 1 25x2 ○ 4mm 900x1000 17,6 25 class 1 25x2 ○ 4mm 1000x1000 19,5 25 class 1 30x3 ○ 5mm 250x1000 9,5 25 class 4 30x3 ○ 5mm 300x1000 11,2 25 class 3 30x3 ○ 5mm 400x1000 14,5 25 class 2 40x3 ○ 5mm 150x1000 8,2 25 class 4 40x3 ○ 5mm 200x1000 10,4 25 class 4 40x3 ○ 5mm 250x1000 12,5 25 class 4 40x3 ○ 5mm 300x1000 14,7 25 class 4 40x3 ○ 5mm 400x1000 19,0 25 class 3 40x3 ○ 5mm 500x1000 23,3 25 class 2 40x3 ○ 5mm 600x1000 27,7 25 class 2 40x3 ○ 5mm 700x1000 32,0 25 class 2 40x3 ○ 5mm 800x1000 36,3 25 class 1

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Modular panels with 15 x 76 mm meshPlate (mm) Connection Dimensions (mm) Galvanized (kg/sqm) Piece No. packaging Maximum load 25x2 ○ 4mm 150x1000 5,3 25 class 4 25x2 ○ 4mm 200x1000 6,8 25 class 4 25x2 ○ 4mm 250x1000 8,2 25 class 3 25x2 ○ 4mm 300x1000 9,7 25 class 2 25x2 ○ 4mm 400x1000 12,7 25 class 1 25x2 ○ 4mm 500x1000 15,6 25 class 1 25x2 ○ 4mm 600x1000 18,6 25 class 1 25x2 ○ 4mm 700x1000 21,5 25 class 1 25x2 ○ 4mm 800x1000 24,5 25 class 1 25x2 ○ 4mm 900x1000 27,4 25 class 1 25x2 ○ 4mm 1000x1000 30,4 25 class 1

Class 1 – Compact crowd – pedestrian capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category E. Dynamic load 600 daN/m2 Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 2 – Car capacity D.M. of 14 January 2008 – 3.1.4 Table 3.1.II – Category F. Dynamic load 1000 daN applied over an area of 200 x 200 mm with a total ground mass up to 3000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 3 – Light truck capacity. Dynamic load 3000 daN applied over an area of 400 x 200 mm with a total ground mass up to 6000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

Class 4 – Articulated lorry capacity. Dynamic load 9000 daN applied over an area of 600 x 250 mm with a total ground mass up to 45,000 kg Material: S235JR steel Sigma yield strength = 23.5 daN/mm2 Sigma comparison = 22.38 daN/mm2 Max. deflection = 5 mm Max. deflection = 1/200 Ln

- + Completed projects

-

- + Accessories

-

Tank Patented Grating Clamp

1. Traction screw 2. M-shaped clamp 3. Patented grating clamp 4. Standard lock nut 5. Special lock nut

Standard Grating Clamp

Corner Bars

Anti-Theft Kit

- + Special Processes

-

Shaping

Each building and every situation has different shapes and needs. It is for this reason that Baldassar has established a specialised technical department to be able to create products with special shapes and patterns. Thanks to the shaping process, each grating element can have the most suitable contour for an easier insertion and installation, with minimum waste material.

Banding

As a result of the banding process, the grating panel can have various standard finishes or be designed according to the customer’s design, such as with round, bevelled, square or shaped bands. This deformation process is fully designed and performed inside the Baldassar premises.

Calendering

Thanks to the cutting-edge equipment, our technical department is able to deform the metal profiles according to specific designs, by giving it a circular curvature. The process is carried out in-house; therefore, there is no need to wait for third-parties to be carry out this process.